Torque or Torque and Angle bolt Tightening?

Torque is an affordable, relatively accurate method of measuring the work required to rotate a bolt. The challenge is turning the fastener and stretching the bolt to a tension suitable to withstand the forces that the bolted joint is subjected to in a controlled assembly environment.

But Materials change. The condition of the materials change. Different joints not only have different torque requirements they also different aspects of relative importance to safety. Think about safety-critical joints.

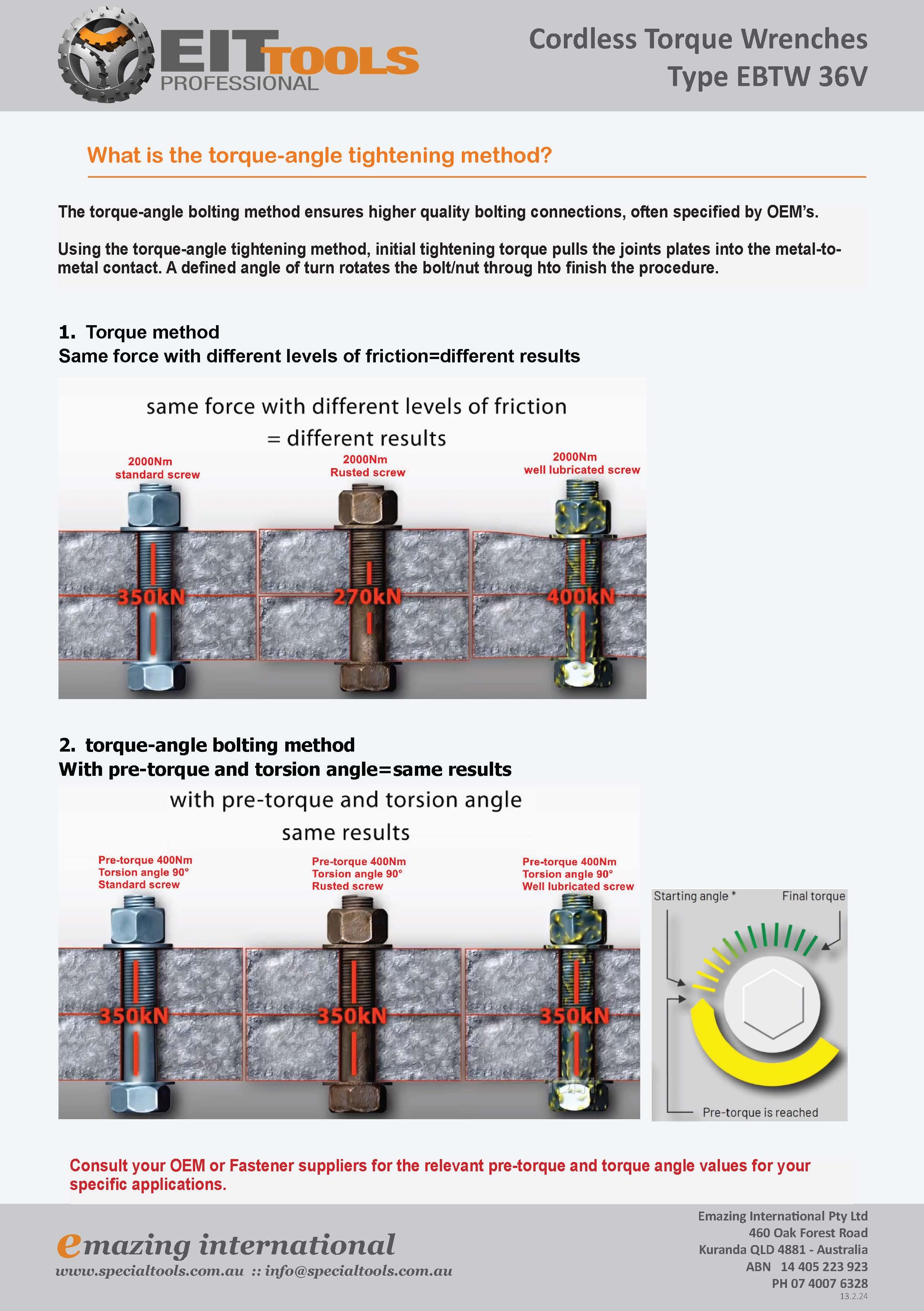

By using torque plus angle, we use torque as a way to measure the snug point of the fastener. Snug is the point where all additional rotation results in bolt stretch or tension. Now by switching to measuring the rotation, or angle, we can turn the fastener an appropriate number of degrees to achieve the desired bolt stretch.

Despite uncontrollable, often erratic, influences on the torque measurement, torque and angle are significantly more accurate. That increase in accuracy comes from knowing the fastener materials, thread pitch, and the nature of the fastener, (blind hole, through-hole, etc.) With thread pitch, you know how far the faster will travel based on the number of degrees it is rotated.

The trade-off for more precise measurement is sacrificing speed. An impact wrench for example is quick to get the lug nuts tight so your wheels don't fall off. Given the speed of application and operator variance, people can find that their rotors are warped. This was not caused by overheating of the brakes. That came from an uneven torque application from the impact gun.

In walking customers through the operational features of our 36V Cordless Battery Torque Wrenches capable of applying torque and angle, a common comment we hear is that the operators new to torque and angle will have to slow down a bit before they start to become comfortable and experienced with this method. Typically, everyone is fine with the change of pace as safety is more important than speed. In the industrial assembly world, trade-offs are a given. If greater accuracy is critical, then a different fastening strategy is required. Torque and angle are likely to be the basis of that strategy.

For a quick overview on how torque is affected by different types of the bolts, please have a look at the image below:

For more information and assistance in regards to your specific application, please contact us